Cracked Heat Exchangers

Scam alert! Each heating season, numerous Dayton heating contractors are tempted to lie about cracked heat exchangers in an attempt to sell more furnaces. To be clear, a gas furnace heat exchanger can crack and this is a serious, sometime life-threatening problem. But how can you as a homeowner know if your service technician is just trying to scare you into a new furnace?

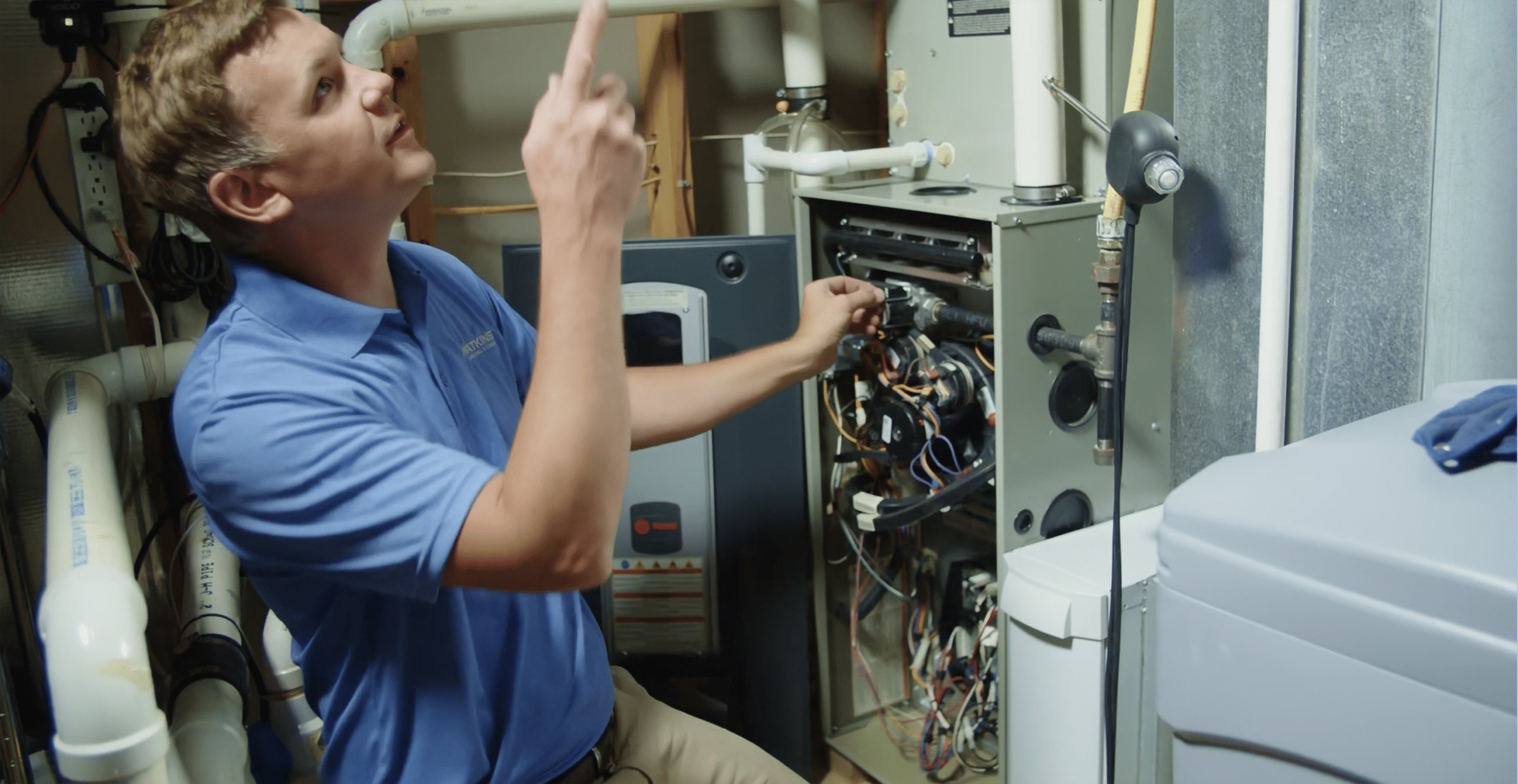

We give free second opinions on cracked heat exchangers. Our techs can walk you through their diagnostic process so you can see for yourself and be confident in the decision to repair or replace. In a typical heating season, our NATE-certified service technicians confirm only about 10% of these as real cracks. Sometimes we find an honest mistake and we can repair the real problem and move on. In extreme cases, we find absolutely nothing wrong with the furnace, only unethical scare tactics to sell a new heating system.

In this post, we’ll share a few tips that can help homeowners recognize heat exchanger fraud. Let’s first cover the function of a furnace heat exchanger, the dangers of a cracked or rusted heat exchanger, and the likely causes.

What Is a Furnace Heat Exchanger?

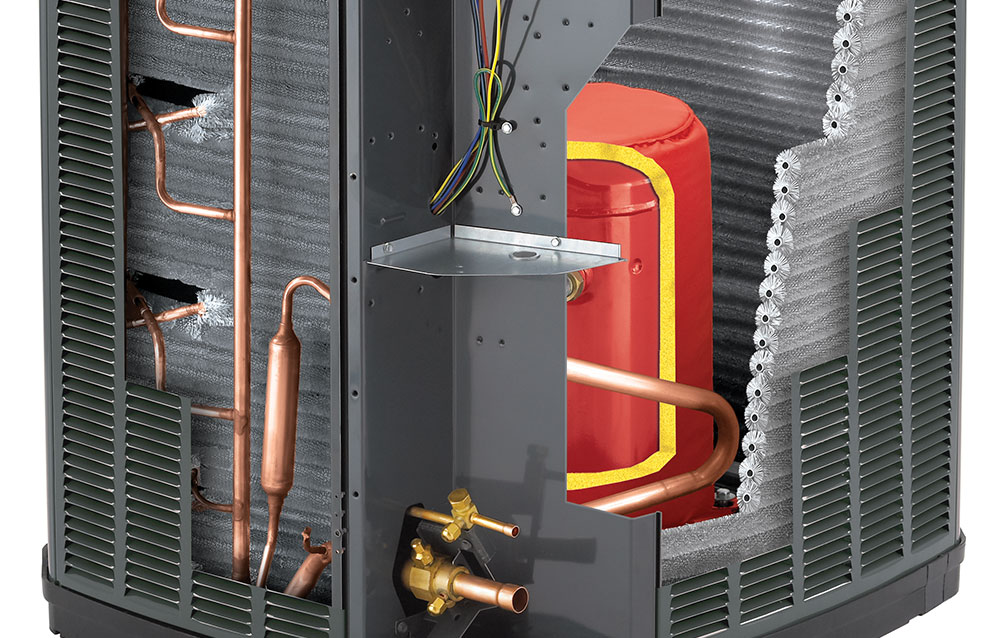

The heat exchanger plays a central role in any furnace. It separates the warming flame and combustion byproducts from the air in the home. Many people in the Dayton and Cincinnati areas heat their homes with fossil fuels such as natural gas, propane, or fuel oil. When fossil fuels burn, they produce fumes containing carbon monoxide, carbon dioxide, water vapor, and nitrous oxide. Some of the products of the combustion process can be dangerous or even deadly if allowed to concentrate in your home.

A furnace uses the heat exchanger to contain these combustion byproducts and safely conduct them to the chimney or flue pipe while efficiently transferring the valuable heat into the home. Basically, the burning fuel warms the heat exchanger which then safely delivers warm air to your home.

What Is a Cracked Heat Exchanger?

A cracked heat exchanger is a break in the metal component that separates your furnace’s combustion gases from the air in your home. Think of it as a protective barrier, and when it’s damaged, dangerous gases like carbon monoxide can leak into your home’s air (For more information on carbon monoxide safety, visit EPA’s Carbon Monoxide Poisoning Guide). These cracks can develop over time due to wear and tear or issues like overheating. While cracked heat exchangers are a serious issue, some contractors make false claims of heat exchanger damage to get you to buy a new furnace.

At Watkins Heating & Cooling, we’ve seen it all. One customer was told by another company that their furnace was beyond repair due to a crack. When we arrived, our diagnostic tools showed no cracks—just a dirty flame sensor causing the issue. Another case involved a truly cracked heat exchanger in a 15-year-old furnace, where we safely replaced it with a properly sized system. These real world examples highlight our NATE-certified technicians’ expertise and commitment to honest service. They also emphasize the importance of spotting the true signs of a cracked heat exchanger to avoid falling for scare tactics.

What Are the Dangers of a Cracked Heat Exchanger?

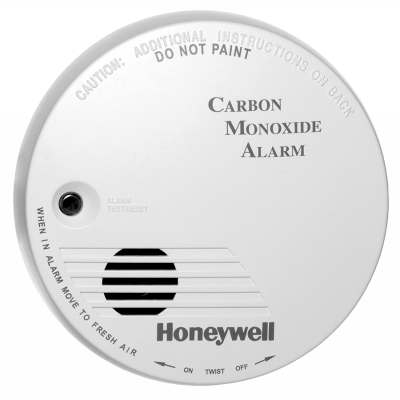

If the heat exchanger rusts through or cracks, flue gases, including deadly carbon monoxide could leak into the home resulting in illness and possibly death of the occupants. Carbon monoxide poisoning can produce headaches, flu like symptoms, and even death. Cracked heat exchangers allow air from the furnace fan to enter the heat exchanger disrupting the flame and causing incomplete combustion. This produces even more carbon monoxide in the flue gases than usual while the damaged heat exchanger allows this toxic mix to enter your home.

What to Do If You Suspect a Cracked Heat Exchanger:

If you do think your furnace might have a cracked heat exchanger, it’s important to act quickly but also carefully. Taking the right steps can ensure your safety while helping you avoid unnecessary repairs or replacements. Here’s a simple guide to follow if you suspect an issue:

- Turn Off Your Furnace: Switch off the gas valve to shut off the furnace and stop combustion. This keeps any potential gas leaks from getting worse while you figure out the next steps.

- Check Your Carbon Monoxide Detectors: Make sure your detectors are working and showing a reading of zero. If they’ve gone off, move your family outside and call for help right away.

- Schedule a Professional Inspection: Reach out to a trusted HVAC company to take a closer look. A reliable technician will explain the issue clearly and help you decide on the best solution.

- Ask for Visual Proof: If a technician has condemned your gas furnace due to a cracked heat exchanger, you should demand to see the crack with your own eyes when they replace the furnace. An honest company should have no problem standing behind their diagnosis. With the heat exchanger removed, the crack should be obvious even to the untrained eye. If the problem is not evident, make the company reinstall your old furnace and leave an online review to protect other homeowners.

Signs and Symptoms of a Cracked Heat Exchanger

What are the telltale signs that your furnace has a faulty heat exchanger? A professional HVAC technician will look for two main symptoms: flame roll-out or a high CO reading in the flue pipe.

Flame roll-out occurs when flames fail to draft properly into the heat exchanger, spilling into the furnace’s control compartment. This can trip safety features or even melt wiring. While subtle at first, it becomes more obvious as the problem worsens, eventually shutting down the furnace. If roll-out happens when the blower starts, it’s often a sign of a cracked heat exchanger.

Technicians use a combustion analyzer to measure flue gases, including carbon monoxide. Normal CO levels range from 10 to 50 ppm in the flue and should always read 0 ppm in your home. Anything over 100 ppm in the flue typically points to a crack causing incomplete combustion.

As a homeowner, there are a few symptoms you can look for to indicate potential heat exchanger problems. These signs can help you spot issues early:

- A visible break or crack in the metal of the heat exchanger

- Rust or corrosion around the heat exchanger

- Unusual smells, like a strong, metallic odor

- Yellow, flickering, or weak flames instead of steady blue – if you can safely observe the burner compartment, any flame that isn’t blue and stable could indicate trouble

- Soot buildup around the furnace or flue pipe. In high-efficiency furnaces with PVC flue pipes, black or white soot inside the pipe may signal poor combustion

- Tripped carbon monoxide detectors in your home

- Short cycling, where the furnace turns on and off more frequently than usual

If you notice any of these symptoms, it’s time to call a trusted HVAC professional for an inspection.

What Is the Cause of Heat Exchanger Cracks?

An overheating furnace causes nearly all premature heat exchanger cracks. When a furnace cannot get enough airflow, the heat exchanger overheats and suffers excess stress from expansion and contraction. Over time, the heat stress causes cracks near weak areas such as bends or welds.

The most common cause of an overheated heat exchanger is as simple as a dirty air filter or blocked registers. A clogged air filter restricts airflow through the furnace, overheating the heat exchanger, and eventually resulting in stress cracks. As the furnace overheats repeatedly, the crack gradually opens wider and causes serious problems.

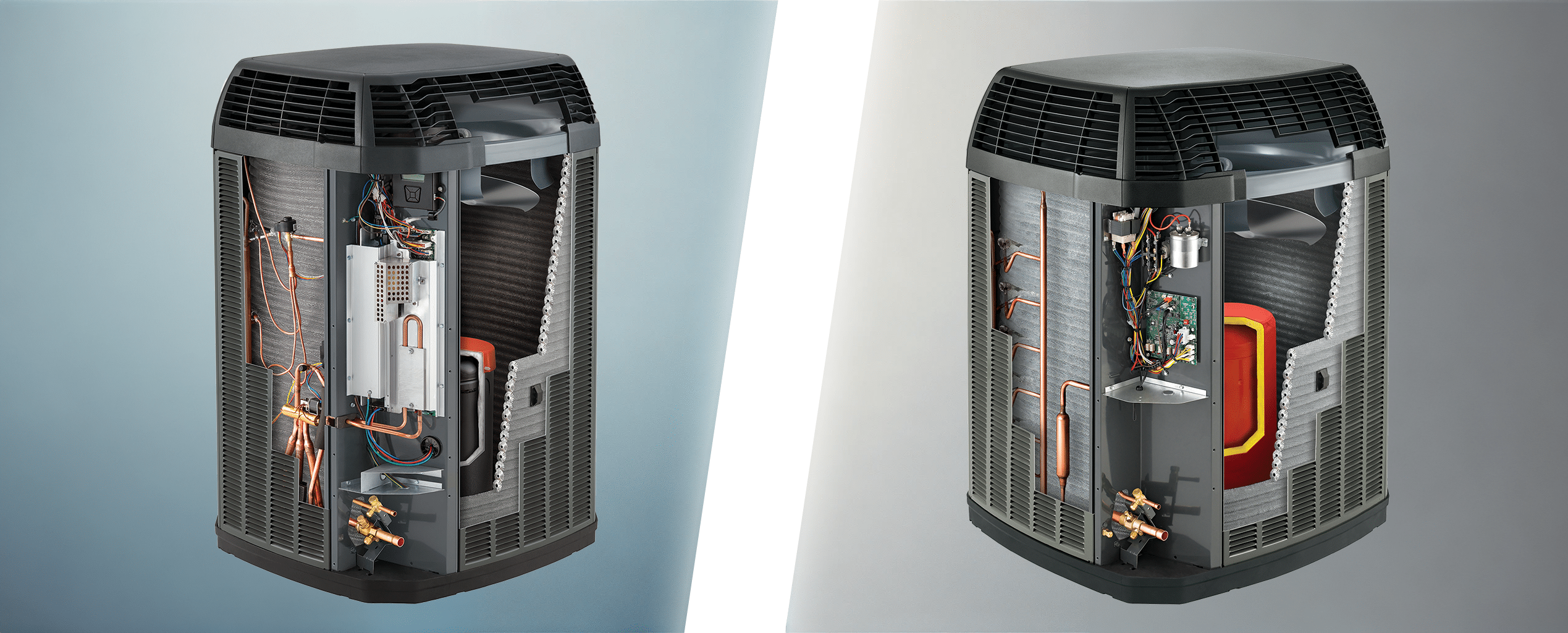

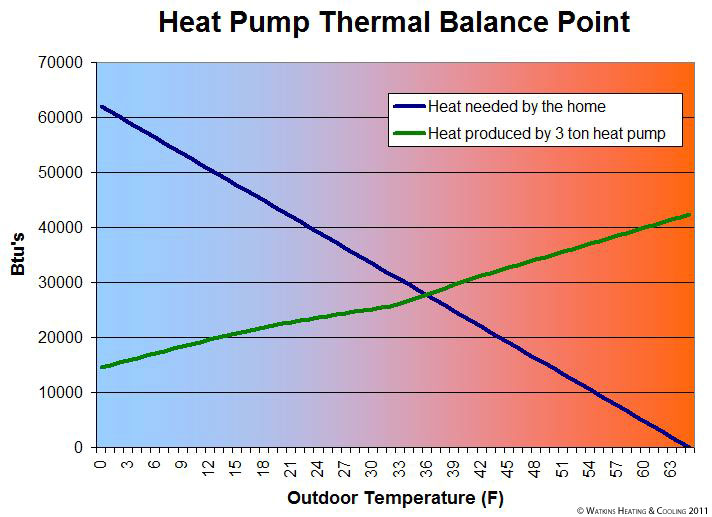

An over-sized furnace can also cause overheating and heat exchanger cracks. We frequently see a large furnace installed with too little ductwork. A furnace installed with under-sized ductwork will lack proper airflow and suffer a similar fate as that of a clogged air filter.

What Is the Cause of a Rusted Heat Exchanger?

When a large furnace has enough ductwork but serves a small home, we frequently see rusted heat exchangers. Fossil fuel combustion produces water as one of its byproducts. When a furnace first lights, the hot flame contacts a cold heat exchanger and water vapor from the flame condenses on the inside of the cool (room temperature) heat exchanger. After less than ten minutes of run time, the heat exchanger reaches full operating temperature and the condensation evaporates. An over-sized furnace heats the home so quickly that the furnace shuts off after only a few minutes, so the heat exchanger stays wet and rusts from the inside out. The frequent cycling of an over-sized furnace also increases the expansion – contraction heat stress on the heat exchanger.

What Is the Cause of a Clogged Heat Exchanger?

A heat exchanger clogs when it fills with soot and no longer allows free flow of combustion gases to the flue pipe. This is common in fuel oil furnaces when they are neglected or have not been tuned properly.

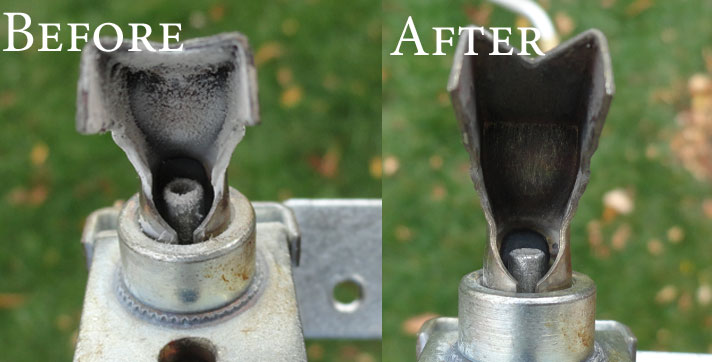

Propane and natural gas furnaces rarely produce soot, but it is possible with poor setup or a design problem from the manufacturer. This was the cases with high efficiency furnaces produced by Carrier and Bryant about twenty years ago. Rather than use stainless steel in the secondary heat exchanger, they applied a special coating to the inside to protect it from corrosion. As a small amount rust forms under the paint, the coating begins to bubble and collapse on itself. The corrosion then accelerates as more of the protective coating delaminates and the heat exchangers clogs with rust and soot.

This is a great example from a Bryant 355CAV furnace that is only 13 years old. The coating began to separate from the metal restricting flow through the heat exchanger and producing soot. Once the combustion process began sooting, the secondary heat exchanger quickly clogged, shutting down the furnace.

Proper Diagnosis of a Failed or Cracked Heat Exchanger

Diagnosis of a cracked heat exchanger typically starts with a no-heat service call. A cracked heat exchanger allows air from the furnace blower to interfere with the flame causing it to turn yellow, flutter, or even roll out of the combustion chamber. Flame rollout will trip a safety switch and shut down the gas furnace.

Your first warning sign of a heat exchanger scam is when an HVAC technician finds a crack during a tune-up and red-tags your unit when the furnace seems to be running just fine. While big cracks start as small ones, some technicians will search for anything that looks like a crack in order to sell a new furnace and earn a commission.

We’ve even seen some technicians draw a line on the heat exchanger with a pencil, show the homeowner the line through a fiber optic camera, and convince them they are looking at a dangerous crack. In 2009, the AHRI published a guideline for inspecting heat exchangers which states: “Any crack or hole that is big enough to affect combustion will be easily visible to the naked eye. Do not use water, cameras or smoking agents to check for leaks. Furnace heat exchanger joints are not hermetically sealed, so a small amount of leakage is normal.”

You can read more about industry standards from the AHRI Heat Exchanger Inspection Guidelines.

In most cases, a true crack will disrupt the flame and produce a carbon monoxide reading in the flue above 50ppm. The technician should be able to show you the flame roll-out and the carbon monoxide reading on his combustion analyzer. If the CO is leaking into your home, it should set off your carbon monoxide detector. If you suspect a wrong diagnosis, call us for a free second opinion.

Is It Safe to Run My Air Conditioner When the Furnace Heat Exchanger Is Cracked?

Yes! The air conditioner needs a blower to move cool air through the duct system and the blower is normally part of the heating system. If you have a dangerous cracked heat exchanger, you can close the gas valve but leave the electric on to the furnace. This will prevent the burner from lighting and producing a carbon monoxide leak while allowing the blower to operate and cool your house through the summer.

How Much Does It Cost to Repair or Replace a Damaged Heat Exchanger?

Unfortunately, cracked heat exchangers itself cannot be repaired. When a heat exchanger cracks or rusts through it must be replaced. This does not necessarily mean the whole heating system must be replaced. Because the heat exchanger is at the core of the unit, nearly the whole furnace must be disassembled, like changing the engine on a car. Even if the parts are covered under warranty, the labor and freight will start around $900. Without a warranty, a heat exchanger replacement could run $2,500 or more. It usually doesn’t make financial sense to spend this much on an old heating system.

The problem with replacing a heat exchanger is that the central cause of the problem has not been addressed. In my opinion, heat exchanger failure is usually due to the furnace being oversized for the house or the duct work. The best solution is to replace the whole furnace with a right-sized furnace (typically 1-2 sizes smaller). When you add up utility rebates, tax credits, factory rebates, and the energy savings of a properly sized furnace, a furnace replacement can actually be cheaper than repairing the old furnace.

If you would like more info on cracked heat exchangers or if you need to schedule a free second opinion, feel free to call our Watkins Heating & Cooling office at 937-748-0220 or reach out to us below: