What Causes Refrigerant Leaks in Air Conditioners

If your air conditioning system leaks refrigerant, it can lead to major problems such as lower energy efficiency, higher bills, and a shorter lifespan for your HVAC system.

We’re here to guide homeowners in identifying refrigerant leaks, pinpointing the root causes, and discovering how to fix them. Our ultimate goal at Watkins Heating & Cooling is to keep your AC running optimally and ensure a cool and comfortable home environment.

The Myth of An Air Conditioner Using Up Freon

Many homeowners think that, over time, an air conditioner uses refrigerant. The thought is that a long, hot summer can leave a perfectly good air conditioner “winded” and low on refrigerant. Many customers think, “We just need to tune up the A/C and top up the coolant, right?” However, the reality is that air conditioning units and heat pumps do not consume Freon. Refrigerant is not fuel, so the AC is not consuming it, and in theory, it is not something that should ever have to be charged or changed. The refrigerant system in an air conditioner or heat pump is a sealed loop that should never “use up” or run out of refrigerant. The only resource that is expended is electricity.

So, if the refrigerant is not consumed in the process of cooling your home, how is it lost?

What Can Cause an Evaporator Coil to Leak?

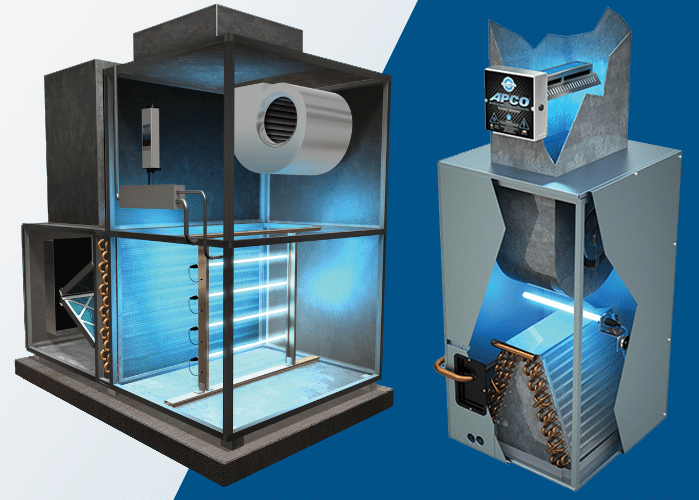

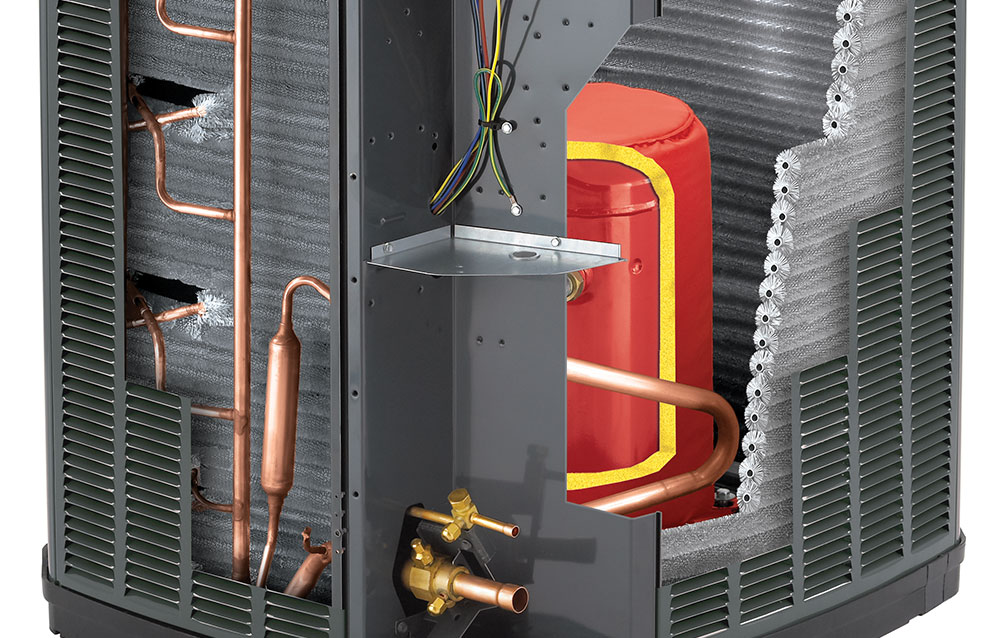

In our experience, if there is a Freon leak in your air conditioner, 9 times out of 10, the leak will be located in the copper tubing of your evaporator coil. The location is nearly always in plate-fin copper tubing, which is made paper thin for maximum thermal efficiency. Indoor coils also leak more frequently than outdoor coils because the average indoor space is chalked full of pollutants. In fact, studies by the EPA have found indoor air to be approximately 2 to 5 times more polluted than outdoor air on average.

This leads to the primary cause of refrigerant leaks…

Formic Acid Corrosion Causes Freon leaks

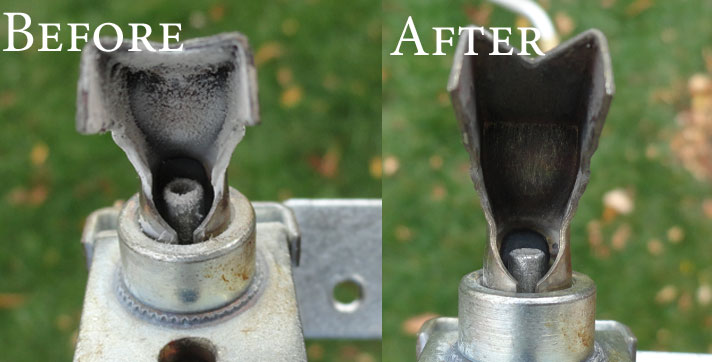

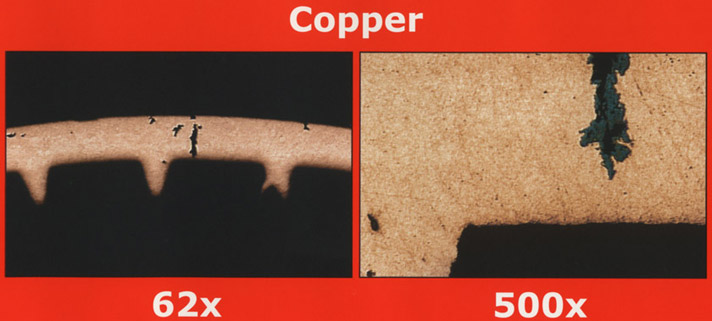

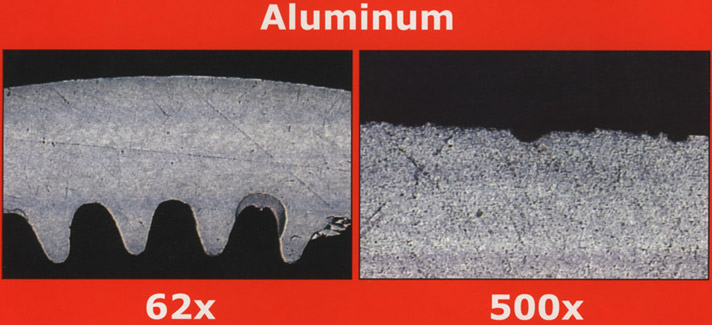

Formicary Corrosion happens when the contaminants in your home’s air mix with water on the indoor coil to create formic acid, a mild acid that attacks copper. Over the course of several years, this acid bores microscopic holes into the copper tubing creating tiny pinhole leaks. We call them champagne leaks because if you were to plunge the evaporator coil into a water tank, you would see hundreds of very fine bubbles.

Engineers at Trane, one of the leading air conditioning manufacturers, were some of the first identify this as the culprit behind coil refrigerant leaks. They discovered that formaldehyde in homes was turning into formic acid on the evaporator coils, gradually corroding pinhole leaks in the copper tubes over several years. Formaldehyde, a significant indoor air pollutant, has been infamous for its high concentration in situations like the FEMA trailers for Katrina victims. But even in the air inside the average American home, there are detectable levels of formaldehyde, leading to the inevitable AC Freon leak.

For years, the air conditioning industry has favored evaporator coils made of copper because of the metal’s ductility and excellent heat transfer, but studies like Trane’s proved that copper was particularly vulnerable to formicary corrosion. To make matters worse, the industry started using thinner copper tubes to help meet the Department of Energy’s increased standards. This meant that the acid corrosion can penetrate newer model indoor coils much faster. After trying various coatings with little effect, the industry has finally adopted all-aluminum indoor coils, which is drastically reducing leaks.

Everyday Wear and Tear

Another cause of ac refrigerant leaks, particularly with an older AC unit, is attributed to the natural aging process. Over several years of use, every HVAC system undergoes varying degrees of natural wear and tear, including weakened connections and deteriorated rubber seals around valves and fittings. Regular tune-ups certainly help detect these issues and fix them before they become a bigger problem. AC units over 15 years old will all have some level of aging, and sometimes, this can lead to a coolant leak.

Mechanical Vibrations

There are a few different elements that could cause excessive mechanical vibrations in your air conditioning unit, and occasionally, our HVAC technicians see this lead to leaking refrigerant. It’s not uncommon for two copper lines to cross inside an AC unit. Over time, normal vibration from the compressor will cause the lines to rub on each other, eventually creating a large hole. Manufacturers protect against this by securing the tubing and using rubber isolators. Over the years, these can decay and lead to big issues.

Physical Damage

Generally, when we see physical damage it’s to the condenser coil. The condenser coil’s outdoor location makes it susceptible to environmental factors like severe weather and even dogs who like to hike a leg and pee on the unit, leading to rapid corrosion of the aluminum. Our technicians have also seen the outdoor unit hit with weed whackers and run over by riding mowers and student drivers. We’ve even seen the neighbor’s kid shoot a condenser coil with a pellet gun!

One potential way to prevent physical damage is to have your AC unit installed on the wall elevated off the ground or to have some fencing around the unit.

Factory Defects

With today’s quality controls it’s rare, but sometimes air conditioners leave the factory with a defect. If the unit loses its Freon charge shortly after installation, the cause may be a factory defect. Corrosion and vibration take several years to impact the air conditioner. A problem in the first year is likely either a faulty braze joint by the installation team or a weak joint made in the factory.

Assembly joints inside the air conditioner are made in a factory by a combination of robots and humans. If the robot is calibrated wrong or the human had a bad day, the connection may fail shortly after install. Trane sets itself apart with some of the most thorough testing in the air conditioning industry. Multiple quality checks during their process make it exceptionally rare for any Trane coil to have a defective joint from the factory.

Improper Cooling System Installation

The HVAC installer also brazes the field joints on-site at your home. A faulty field joint is easy to find and fix since the connections are out in the open. Our install process including a thorough test with high-pressure nitrogen followed by a deep vacuum confirmed by a micron gauge. Any problems with the field joints become very obvious with this two-step quality control process.

It’s important to note that low refrigerant levels don’t always mean a leak. We often receive calls at Watkins Heating & Cooling from customers with low Freon who had their HVAC system installed by other companies. When our team finds low coolant levels in these air conditioning systems, it’s often because the initial HVAC installer did not set the coolant levels correctly. The A/C isn’t low because it leaked; it was low from the very start.

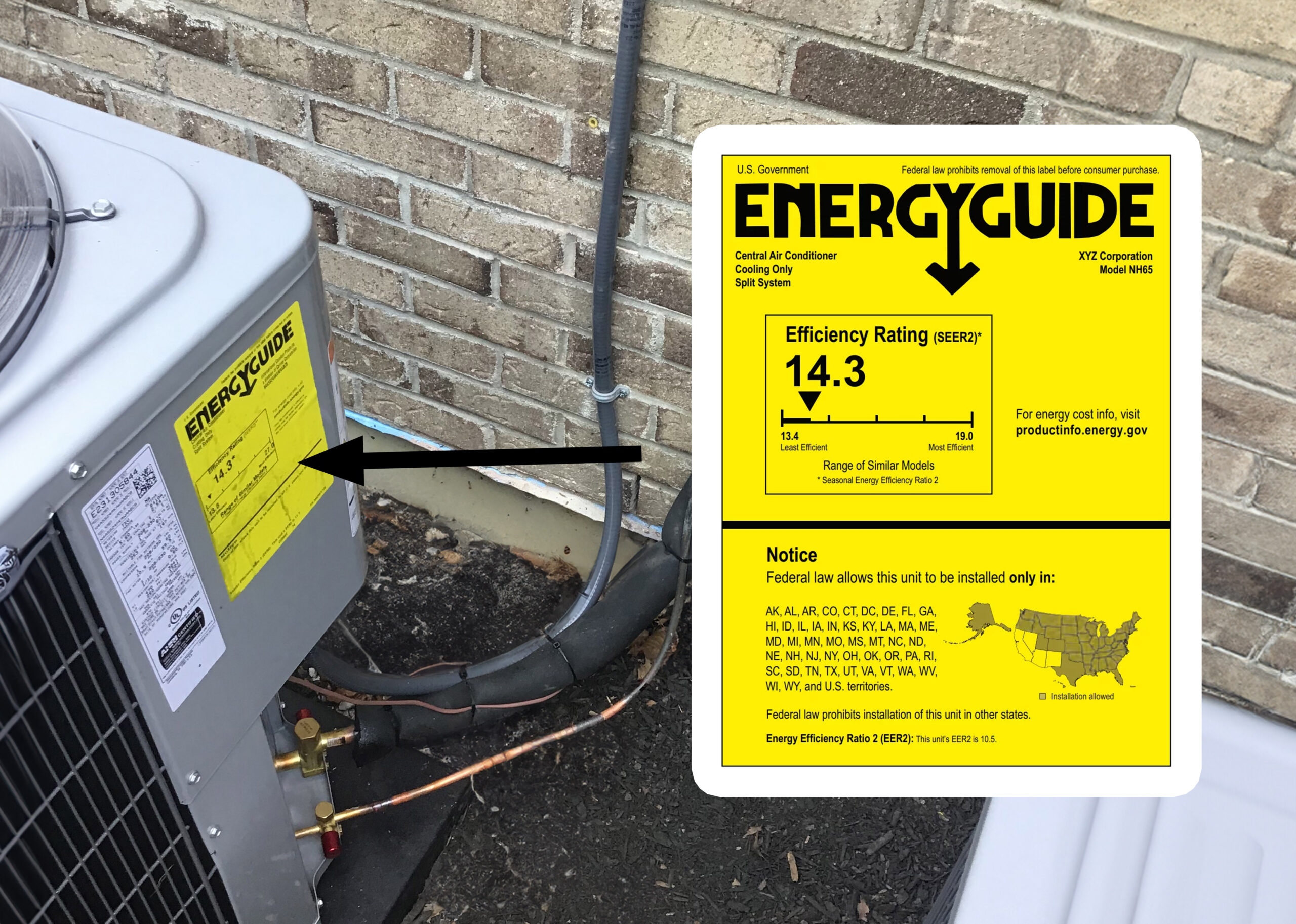

Air conditioners come preloaded with a standard refrigerant charge at manufacturing, typically around 5 or 6 pounds. This factory charge is only enough for very short linesets, and the air conditioner should be fine-tuned after installation. Standard practice for many of our competitors is simply to release the charge and then leave without taking the time to complete a proper commissioning.

At Watkins, we take an extra hour after installation to make fine-tuned adjustments. Our technicians use digital gauges to dial in the perfect pressures and “sub-cool” so that the efficiency and capacity meet the manufacturer’s specifications.

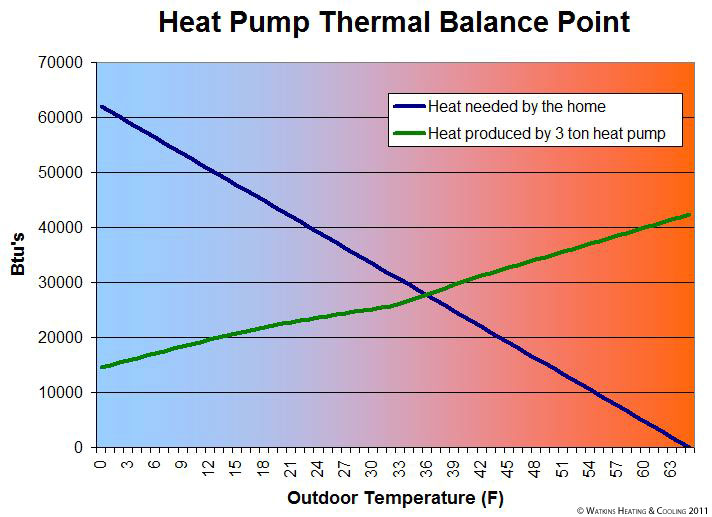

Research shows that being off by as little as 10% in refrigerant level can lead to a 10-20% drop in energy efficiency! The scary part is that the units in the study were still cooling just fine. They were simply using more electricity than necessary. So, while you might have purchased a new AC unit with a high SEER rating of 15, poor installation and startup could effectively reduce its efficiency to a performance equal to that of a 12 SEER unit! This means that you’re not getting the efficiency you paid for and it will cost you in the long run.

Signs of an AC Refrigerant Leak

Now that you know the root causes leading to AC refrigerant leaks, let’s explore some of the signs you might notice if your cooling system is not at its best.

Lack of Air Conditioning System Airflow

This is the most obvious sign of a refrigerant leak that you’re likely to notice: when your air conditioner is running, but it’s not blowing cool air. If your air conditioning system is turned on, but the air coming out of the vents is not cool, we often find that the air conditioner is low on coolant. All the components of the A/C can be operating properly, but, without the correct Freon levels, the A/C cannot cool your home. If this is something you’re dealing with right now, your first step is to get an expert diagnosis so you know exactly what’s causing the issue and your options to fix it.

Air Conditioning Unit Freeze-Up

Another common sign of a coolant leak is a frozen evaporator coil. It may sound counterintuitive, but when your Freon levels are low, it can actually cause your coils to become excessively cold and ice up. When the Freon levels are correct (about 125 PSI for R-410A refrigerant), the indoor coil temperature gets down to about 40 degrees Fahrenheit. This cool temperature condenses tons of moisture from your air, efficiently removing humidity while cooling your home. If the air conditioner refrigerant levels drop and the pressure falls below 100 PSI, the coil’s temperature will drop below 32 degrees, and the humidity that condenses on the coil will quickly freeze. You’re most likely to notice the ice forming around the insulated tubing coming out of the cooling unit. Sometimes the first sign may be water puddling on the floor because the drain pan is blocked by ice.

Note that while a frozen coil often indicates low Freon levels and a possible leak, a clogged air filter or bad indoor fan motor can also cause similar freezing. To determine which you may be dealing with, we recommend turning off the cooling system to thaw, changing the filter, and restarting to see if the issue persists.

Increase in Indoor Humidity

As we explain here, the refrigerant works in your AC system to cool your home AND remove humidity. So, when there isn’t enough refrigerant… the humidity will be higher! Moisture levels will rise and you might feel the air in your home gradually become heavier and stickier, making hot days feel even hotter. This is an early warning sign of a coolant leak, so get your A/C checked out right away.

Spike in Energy Bills

If your air conditioner has a refrigerant leak, you’ll feel the effects is significantly higher energy bills. You may think that just putting some more Freon into the system will fix your energy bills, but a top-off is only temporary unless you fix the problem. While it may cool for several months, it will only maintain peak efficiency for a few days after it’s recharged. Unless the leak is repaired, the refrigerant level is already dropping, and your efficiency will be getting worse every day.

If you’re getting a recharge, make sure the technician does a full leak search to find the root problem and get your A/C working correctly. While the repair may be expensive, sometimes it can be an easy fix. No one wants to waste electricity, let alone have their precious new coolant leak out right away.

Hopefully we’ve helped you gain a clearer understanding of the causes and symptoms of a refrigerant leak. If you’ve noticed one of the signs above, you should take action right away before Freon leaks cause more damage to your air conditioner. To see estimated costs to repair refrigerant leaks, check out our page on AC repair pricing. A no-hassle service call is the surest way to know the real problem with your air conditioner and we always have friendly, professional techs on standby. Give us a call or simply fill out the form below to book a service appointment!